Description

Cable Conduit & Sub Ducts

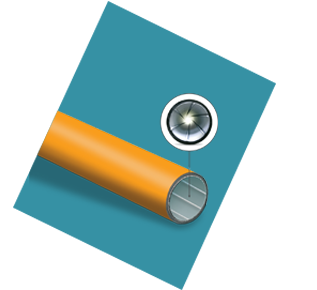

KAI’s HDPE Corrugated Cable Conduits and Sub Ducts are primarily used to serve in electrical and telecommunication installations. They are 100% produced in Kuwait. Utilizing a modern twin-wall technology by using state of the art extrusion machinery, the conduit’s outer corrugated layer is designed to enhance pipe stiffness, absorb external pressure, and reduce overall weight, while the inner layer comprises of a smooth texture, designed to minimize friction. KAI’s sub ducts are manufactured with the installers benefit at heart. They are smooth on the outside providing for easy insertion into the cable conduit. The inner layer of the sub-duct may be manufactured with or without silicon.

THE CONDUITS AND SUB DUCTS ARE ECONOMICALLY VIABLE AND PROVIDE MANY ADVANTAGES SUCH AS:

♦Long service life

♦Light weight

♦ Excellent strength

♦ Flexible

♦Chemical resistance

♦Leak proof joints

♦ Color coded for easy identification

♦Rodent repelling properties(upon request)

SPECIFICATIONS & STANDARDS

KAI manufactures its Cable Conduits and Sub Ducts in accordance to both KOC and MOC standards.

- Cable Conduits: EN-13476-1

- Sub Ducts: DIN 8074, 8075

CABLE CONDUIT

| NOMINAL SIZE (mm) | ID (mm) | OD (mm) | STANDARD COLOR(S) | STANDARD SIZE |

|---|---|---|---|---|

| 100 | 96.0 | 112.0 | Orange / Black / Grey | 6 meters / 12 meters / Coil |

| 120 | 104.0 | 120.0 | Orange / Black / Grey | 6 meters / 12 meters / Coil |

SUB DUCT

| NOMINAL SIZE (mm) | ID (mm) | OD (mm) | STANDARD COLOR(S) | STANDARD SIZE |

|---|---|---|---|---|

| 25 | 21.0 | 25.3 | Green / Black / Orange | Coil |

| 32 | 27.0 | 32.3 | Green / Black / Orange | Coil |

| 40 | 33.0 | 40.3 | Green / Black / Orange | Coil |

Larger diameters and other colors are available upon request

All diameters are subject to a tolerance level of _ 1%

Sub Ducts may be manufactured with a spiral silicon finish internally.

The silicon finish provides two (2) primary advantages:

♦In this system, the cable is only ever in contact with the low friction liner (silicon)

♦The spiral design of the low friction co-efficient liner will make it easier to blow or pull cables over long distances

CHARACTERISTICS

LIFE SPAN

Conduits manufactured using recycled or poor quality polymers are prone to cracking and failure.

We use only high quality virgin polymers, supplied by reputable material manufacturers. The minimum operational life of a KAI HDPE Corrugated Cable conduit is 50 years.

UV STABILITY

Cable conduits are designed to be buried underground. However KAI HDPE Corrugated Conduits are UV stabilized and can be stored outdoors for up to 1 year.

PACKAGING & HANDLING

Supplied in various lengths and bundles for easy handling.

MARKING

Conduits are marked showing pipe size, standard, and batch number. Additional markings as per the customer’s request may be accommodated.

ACCESSORIES

CONDUIT COUPLER

Leak-free polypropylene (PP) coupler necessary for double socket push-to-fit joints. Standard colors are orange and black.

END CAP

High-quality polypropylene (PP) end cap compatible with the conduits. Standard color is black.

SPACER

Firm two-way polypropylene (PP) spacer designed to minimize movement of sideby- side conduits. Standard color is black.

GASKET

Rubber seal made of high quality EPDM rubber specifically designed to mount on the corrugation of the conduit’s outer surface.

SUB-DUCT COUPLER

Leak-free polypropylene (PP) screw-to-fit joint. Compatible with all lengths and sizes. Standard color is black & blue.

END PLUG

High quality rubber designed to seal Sub-Duct ends when necessary. Standard color is black.

Reviews

There are no reviews yet.