Description

Product Application

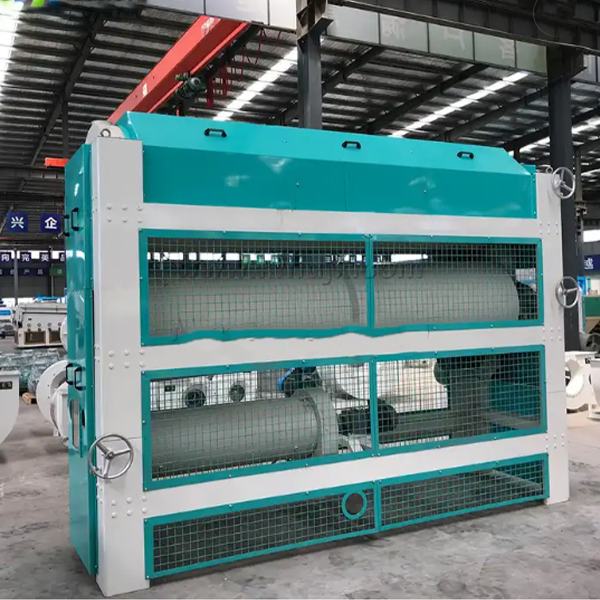

1) Function: gentle grading of all granular materials by length2) Capacity: 5t/h (based on wheat with 3% impurities).

Indented cylinders combine long and short grain separation in one system, separating products by length. They are usually used after the pre-cleaning machine or air screen cleaner. The speed of the cylinders and the flow rate can be adjusted for different processing materials to achieve a maximum quality of product separation.

Working Principle

Left: Series Mode (above for separate both long and short impurities); Right: Parallel Mode

Working part of indented cylinder is the rotating cylinders whose cover is provided with deep drawn spherical shaped pockets (indented cells) for the most precise length separation.

Grains which sizes are smaller than pockets will stay in the indented pockets, and will be lifted with the rotation of cylinder, after a certain distance (adjustable) fall out of the pockets under gravity into the trough, then discharged to the product outlet by auger conveyor. Impurities which are longer than the indent diameter will remain on the inside surface of cylinder and slide out to impurity outlet of cylinder. (Same for long grain and short impurity)

Feature

1 Gentle cleaning and grading of seeds and grains.2 Bolted robust steel structure and compact size.3 Full closed cylinder to reduce the dust.4 Cylinders can be series or parallel as per requirement, driven by individual motor. 5 Quick changeable indented cover, easy to remove the accumulation.6 Easy and adjustable trough positioning.7 Dust aspiration outlet to connect with dust collector.

Reviews

There are no reviews yet.