Description

UNDERGROUND STORAGE TANK

WHAT IS AN UNDERGROUNDTANK?

KAI high-density polyethylene (HDPE) underground tanks are designed to be a key part of both household and commercial septic systems. Septic systems treat sewage waste by using naturally occurring bacteria to treat the waste. Septic systems however are not the only possible use for these tanks as they can be used to store chemicals, and brackish/potable water.

WHY CHOOSE KAI?

With the advancement of technology the days of requiring metal and concrete tanks are long gone. Our state of the art machinery produces the best HDPE underground tanks on the market. The combination of durability and ease of use make these the easy choice. KAI underground tanks are fabricated in custom sizes to match the different sewage loads of various households.

BENEFITS OF HDPE UNDERGROUND TANK

* Polyethylene tanks are significantly cheaper and easier to install.

*Corrosion proof; unlike metal they will not rust

*Light weight and significantly easier to install

* Watertight, and hold in odors with no leakage

* More resistant to tree roots and cold temperatures

*Easier to repair if they become damaged

*Manhole extensions are easy to install

APPLICATIONS

*Sewage

*Chemicals

* Brackish Water

* Fire Reservoir

STANDARDS AND SPECIFICATIONS

To ensure the satisfaction of the end user, we at KAI strictly adhere to internationally recognized standards. Below are the standards we follow.

- CAN/CSA-B66-05

- Welding according to standard DVS 2207-4

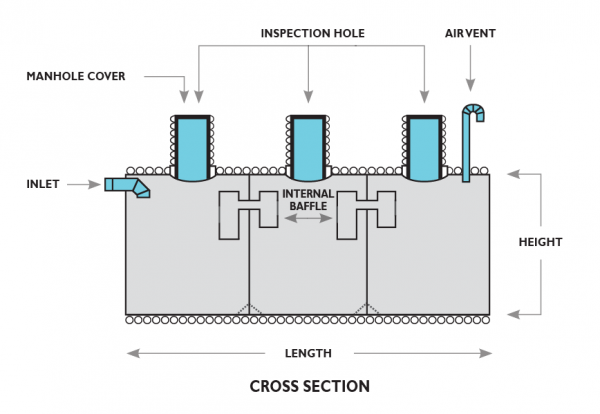

While we are ready to customize a tank upon request, we also have these three standard sizes. The chart below is designed to give you a better understanding of the dimensions of the tank and its accessories.

| CAPACITY (USG) | LENGTH (mm) | HEIGHT (mm)

|

INLET(mm) | AIR VENT(mm) | INSPECTION HOLE (mm) | |

|---|---|---|---|---|---|---|

| 3,000 | 6,200 | 1,600 1,850 | 200 | 110 | 600 | |

| 5,000 | 6,200 | 2,000 2,248 | 200 | 110 | 600 | |

| 7,000 | 6,200 | 2,400 2,648 | 200 | 110 | 600 |

INSTALLATION

*As far away from buildings as possible

* Good road access for tank-emptying vehicles to operate

* Trench should be similar size to the tank

* Flat surface under the tank with no sharp rocks

* We recommend that piping connection is made at least 18 inches below ground level

*Fill with water till it flows into the soakaway pit

*Backfilling shall be conducted in layers of 250 mm thick one at a time

*During backfilling, the soil, sand or aggregates shall be uniformly filled around the tank.

*The practice of backfilling on one side at a time shall be avoided altogether.

* Underground tanks shall be anchored or strapped to the base of the concrete slab prior to backfilling, to resist floating.

* Manhole cover/inspection hole and the air vent are to be slightly above ground.

KEY COMPONENTS

INLET

The access point where the material is entering the tank.

INTERNAL BAFFLE:

Also made of HDPE plastic it is used as a method of allowing liquid to flow between compartments

AIR VENT:

Necessary for dealing with gasses within the tank in a safe manner

MANHOLE COVER:

Used to cover the Inspection Hole(s) and keep the tank sealed

INSPECTION HOLE:

A repurposed corrugated pipe designed to allow easy access and provide the necessary structural integrity

STRUCTURED WALL:

The corrugations on the outer wall absorb pressure from the surrounding environment keeping the contents undisturbed

SUPPORT SYSTEM:

Additional Corrugations added to the sides to increase structural integrity

Reviews

There are no reviews yet.